Our rotary table bearing has two years guarantee period.

Our crossed roller bearing has one year guarantee period.

If any products quality problems, PLS be free to contact us.

After-sales service contact:

Contact person: Mr. Xin

Phone: 86-379-63086182

Mob:86-15236685001

Installation Guidelines for Rotary table bearing

1. Installation

The bearing should be installed with the shaft and bearings sets, and the installment is transition fit. Improper fits will decrease the rotational accuracy and dynamic performance. For example, tight fit will raise the radial preload of the bearing. Then the friction will increase, generate much heat , the load and friction of the raceway will be get up step up. so, the limiting speed and the useful life will drop.

The precision of procession of the shaft and bearing set, the fit of the bearing rings, shaft and the bearing set, will increase the axial runout and the radial runout of the bearing. In order to get high rotational precision, the clearance fit should be close to zero.

*X* In order to make the size of shaft to be easy match with that of the bearing and bearing housing, you can see the certificate of inspection attached with the bearings.

Advice to the bearing fit with the shaft.

The tolerance of shaft is H5. At the situation of high accuracy of rotation and inner ring rotation , the clearance fit should be close to zero, or the the clearance fit will raise the run-out of the bearing. In the case of higher rotation speed and longer run duration , the clearance fit can not pass 0.01mm. For the YRTS high speed series bearings, the clearance fit can not pass 0.005mm.

For the HYZF series bearings, because this kind of bearing have 2 inner rings, the clearance fit should be decided as the size of the smaller ring .

Advice to the bearing fit with the bearing set.

The tolerance of bearing set is J6. At the situation of high accuracy of rotation and outer ring rotation, the clearance fit should be close to zero. If the outer ring does not run, we should use the proposal of clearance fit orthe design which need not radial positioning. For the case of higher rotation speed and longer run duration, theouter ring should not use the design which need radial positioning,and the clearance fit should be at least more than 0.02mm, this can reduce the over load when the bearing occurs much heat.

The selection of the bearing fit.

The rotary table bearings are fastened by bolts, if the outer ring of the bearing is fixed on the stationary parts, we need not use bearing housing to make radial positioning, or select clearance fit, this will make the installment more easily.

If the rotary table bearing inner ring is fixed to stationary parts by bolts, From a functional perspective, the axial direction of the bearing must be held by shaft, and to be close to clearance fit.

For the YRTS high speed series bearings, due to the high rotation speed performance, so the shaft and bearing set have high requirement on the accuracy, you can contact with Hongyuan to get the technical details.

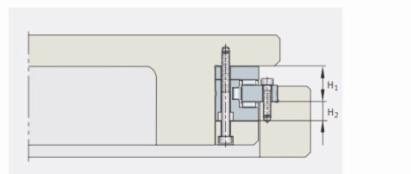

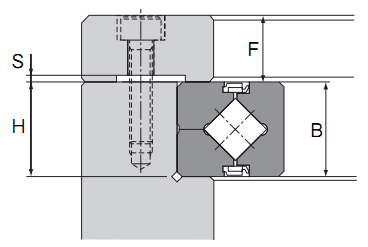

The size requirement on the H1,H2

The height deviation should be as small as possible, H1 (Picture 9) deviation must be controlled by the data in page 15. H2 decides the turbine position in worm gear structure. Please see picture 9, or please see figure 10, the “L” shape inner ring with support ring.

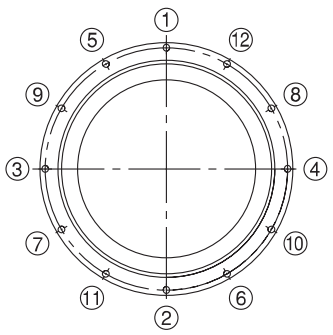

Installation dimension H1、H2(picture 1)

Figure 1

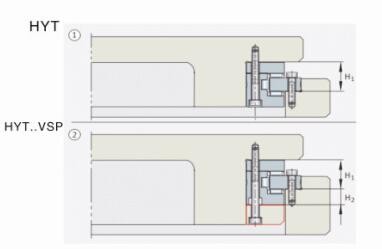

2. The “L” shape inner ring with support ring or without support ring.

“L” shape inner ring’s entire head face have support for YRT VSP bearing for, or do not have support for YRT bearing. Please see piture 2. If “L” shape have the support ring, the rigidity of overturn will be bigger. Support ring(such as turbine ) will not offer.

For “L” shape ring with support ring, the bearing type have a suffix VSP, For example , YRT200VSP. The height of the support ring should be twice of that of the second inner ring.

*X*please advice us the install type when purchase.

Figure 2

3. Installation guideline

Compared with the common bearing, YRT bearings have higher precision. We must take care install, or the precision and useful life will decrease.

The bearings must be taken care when carry. the connecting bolt can against the damage when transport.

In order to make the bearing positioning more easy, the connecting bolt of the bearing must be released before install, and tighten after that.

As given tighten torque MA, tighten the fixing screws in crosswise sequence using a torque wrench in three steps to the specified tightening torque MA.

Step 1, 40% of the MA

Step 2, 70% of the MA

Step 3, 100% of the MA

The steps of outer ring is the same as inner ring.

Please see picture 11

Figure 3

Remark.

1. The install blot grade must be over grade 10.9.

2. The install power only can be on the bearing rings, not on the roller.

3. In the mounting and dismounting of bearing, the units of bearings can not be Splited and can not change.

4. If the bearings rotate hard, please release the Mounting bolt, tighten the fixing screws in crosswise sequenceusing a torque wrench in three steps to the specified tightening torque.

*X* Do not knock the bearing when install it.

Notes: Other Non-regular models installation, Please be free to contact Hongyuan.

Installation Guidelines for crossed roller bearing

1. The design for the shaft and the bearing set and the installment

The design for the bearing set and the fixed flange

Because crossed roller bearings are thin section structure, so you need consider the rigidity of the bearing set and the fixed flange. The outer ring was divided to two parts, if the rigidity of the bearing set or fixed flange and the fixed bolts is not strong enough, the inner rings or outer rings can not fixed uniformly, the bearings will to become deformed. Therefore the contact area of the roller and the raceway will be inhomogeneous, the performance of the bearing will be affected by that.

Bearing Set

The wall thickness of bearing set, please design at the basic of 60% of the bearing section height.

The wall thickness of bearing set:  (D∶Outer ring diameter,d∶Inner ring diameter)

(D∶Outer ring diameter,d∶Inner ring diameter)

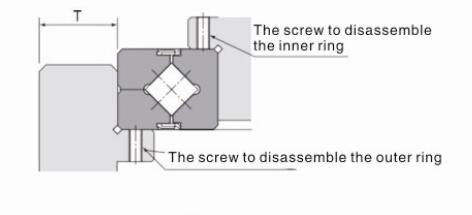

Besides, if the bearing have threaded hole wich is used for disassemble the outer rings and inner rings, the bearings can not be damage when disassembling that.

Figure 4

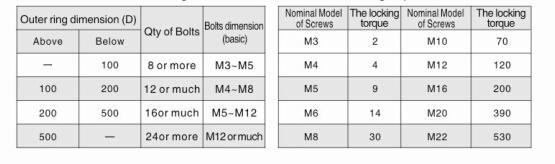

Fixed flange and fixing bolts

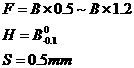

The wall thickness of fixed flange (F) and the gap of that (S), please following below dimensions. Besides, for the fixed bolts quantity, though more fixed bolts, more stable, but as the basic parameters, you can use below table for your reference to make equidistant configuration, you can use suitable torque to screw the bearings.

Figure 5

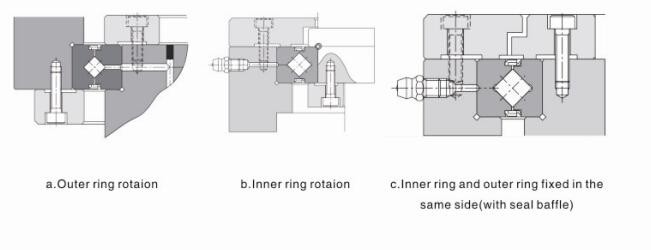

Assemble Example

Figure 6

A. Outer ring rotation B. Inner ring rotation C. Inner ring and outer ring fixed in the same side(with seal baffle)

At the same time, though the material of the shaft or the bearing set is light alloy, the material of fixed flange is advised to use steel. When locking fixed bolt, please screw the bolts tight with the torque spanner. If the bearing set or the fixed flange use the general medium-hard steel, please see the locking torque showed in following table.

Table 1 The QTY and Dimensions of Fixing Boilts. Unit:mm Table 2 The locking torque of the bolts Unit:mm

Table 1

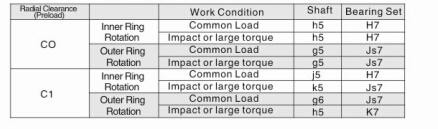

The fit tolerance of the bearing installation.

The fit tolerance of RB series, RE series and RA series, and the fit of RB series, RE series and RA series, please see the combination showed in below table.

Table 3 The fit of RB, RE and RA series

Table 2

Remark:

1, For the fit of clearance CC0, you need avoid the interference fit, or the excessive preload will occur. When the selected clearance CC0 is used on the the robot’s joint or rotating parts. The fits should select the combination of G5 and H7.

2, There is no fit requirement for RU series and HYBH series. But, when there is position accuracy requirement on the installment, we suggest to select h7 and H7.

3, For higher precision bearing fit, please contact with HONGYUAN.

2. Installation notes:

When installs the crossed roller bearings, please carry on according to the below step.

A. Check the parts before installment.

The main axle, the bearing set or other parts must be clean fully before installment, no greasy dirt or the impurity, and make sure the bearings have no burr or the fragments.

B. Put the crossed roller bearings into the shaft or bearing set.

Because the bearing is thin section bearing, it is easy to incline when installing. In order to prevent this problem, please maintains the bearing to be horizontal, while strikes with the plastic hammer lightly, loads the cross roller bearing into the bearing set or the axis step by step carefully, until you checked that the bearing contact with the datum level completely through the sound.

C. The installment of the flange

1, Put the fixing flange on the crossed roller bearings. Shake the flange for several times until the flange fit with the bearing bolt holes.

2,Insert the fixing bolts to the hols. When you turn the bolt by hand, check that there is no deviation to make the bolts can not screw into the bolt holes.

3, As shown below, there are 3~4 stages to lock the fixing bolts completely according to diagonal line repeatedly. When screwing tightly the splitted inner ring or outer ring. Turn the wholly outer ring or the wholly inner ring slightly, the deviation between the inner ring and the outer ring with the main parts can be amended and subject.

Figure 7

Installation Notes:

The separated two parts inner rings or outer rings, when delivery ,we will fit that with the special rivets, bolts

or nuts. When installing that into the system, do not disassemble that. In addition, if you install the isolation

block by error, the rotation system performance will be seriously effected. Do not disassemble the bearings!

(2) The concentricity of the splitted inner ring or the outer ring may have the deviation slightly. Therefore, befo

re installing that, please loosen the fixed bolts of the inner ring or outer ring, then install that after adjust that

with plastic hammer.

3, When installing or disassembling crossed roller bearings, please do not put strong pressure on connected rivets, bolts and rollers.

4, When installs the fixed flange, you must consider the dimension allowance of the installation parts, to make the flange contact well with the inner ring and outer ring from side. Also you can not put too much pressure on the bearings, or the bearings will become deformed, that will affects the bearing rotation flexibility and life.

Bearing notes when using

(1) The bearing may cause a loss on function when impurity enter into the bearing, so please prevent that into the bearing, such as dust or cutting chips. If there is dirt, saw dust, please re-grease the bearing after you clean that with clean white oil.

(2) When the operating temperature exceeds 80 degrees, please contact with Hongyuan.

(3) If the bearings are used in the special operational environment of constant vibrations, dust free room, vacuum, low-temperature or high-temperature, please contact with Hongyuan.

Notes: Other Non-regular models, Please be free to contact HONB.

- YRT rotary table bearing

- YRTS rotary table bearing (high speed series)

- YRTM with integral angular measuring system series

- ZKLDF axial angular contact ball bearing series

- RA series crossed roller bearing

- SX series crossed roller bearing

- CRBH series crossed roller bearing

- RE series crossed roller bearing

- RU series crossed roller bearing

- RB series crossed roller bearing

- XR/JXR series crossed taper roller bearing

- Crossed roller bearing

✉️ bearing20@hyzcgroup.com

📞 +86 15236685001