Installation Guidelines for Rotary table bearing

1. Installation

The bearing should be installed with the shaft and bearings sets, and the installment is transition fit. Improper fits will decrease the rotational accuracy and dynamic performance. For example, tight fit will raise the radial preload of the bearing. Then the friction will increase, generate much heat , the load and friction of the raceway will be get up step up. so, the limiting speed and the useful life will drop.

The precision of procession of the shaft and bearing set, the fit of the bearing rings, shaft and the bearing set, will increase the axial runout and the radial runout of the bearing. In order to get high rotational precision, the clearance fit should be close to zero.

Advice to the bearing fit with the shaft.

The tolerance of shaft is H5. At the situation of high accuracy of rotation and inner ring rotation , the clearance fit should be close to zero, or the the clearance fit will raise the run-out of the bearing. In the case of higher rotation speed and longer run duration , the clearance fit can not pass 0.01mm. For the HYTS high speed series bearings, the clearance fit can not pass 0.005mm.

For the HYZF series bearings, because this kind of bearing have 2 inner rings, the clearance fit should be decided as the size of the smaller ring .

Advice to the bearing fit with the bearing set.

The tolerance of bearing set is J6. At the situation of high accuracy of rotation and outer ring rotation, the clearance fit should be close to zero. If the outer ring does not run, we should use the proposal of clearance fit orthe design which need not radial positioning. For the case of higher rotation speed and longer run duration, theouter ring should not use the design which need radial positioning,and the clearance fit should be at least more than 0.02mm, this can reduce the over load when the bearing occurs much heat.

The selection of the bearing fit.

The rotary table bearings are fastened by bolts, if the outer ring of the bearing is fixed on the stationary parts, we need not use bearing housing to make radial positioning, or select clearance fit, this will make the installment more easily.

If the rotary table bearing inner ring is fixed to stationary parts by bolts, From a functional perspective, the axial direction of the bearing must be held by shaft, and to be close to clearance fit.

For the HYTS high speed series bearings, due to the high rotation speed performance, so the shaft and bearing set have high requirement on the accuracy, you can contact with Hongyuan to get the technical details.

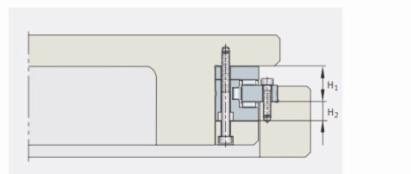

The size requirement on the H1,H2

The height deviation should be as small as possible, H1 (Picture 9) deviation must be controlled by the data in page 15. H2 decides the turbine position in worm gear structure. Please see picture 9, or please see figure 10, the “L” shape inner ring with support ring.

Installation dimension H1、H2(picture 1)

Figure 1

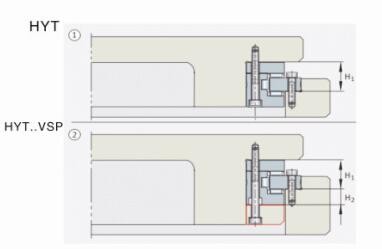

2. The “L” shape inner ring with support ring or without support ring.

“L” shape inner ring’s entire head face have support for HYT VSP bearing for, or do not have support for HYT bearing. Please see piture 2. If “L” shape have the support ring, the rigidity of overturn will be bigger. Support ring(such as turbine ) will not offer.

For “L”shape ring with support ring, the bearing type have a suffix VSP, For example , HYT200VSP. The height of the support ring should be twice of that of the second inner ring.

*X*please advice us the install type when purchase.

Figure 2

3. Installation guideline

Compared with the common bearing, the HYT bearings have higher precision. We must take care install, or the precision and useful life will decrease.

The bearings must be taken care when carry. the connecting bolt can against the damage when transport.

In order to make the bearing positioning more easy, the connecting bolt of the bearing must be released before install, and tighten after that.

As given tighten torque MA, tighten the fixing screws in crosswise sequence using a torque wrench in three steps to the specified tightening torque MA.

Step 1, 40% of the MA

Step 2, 70% of the MA

Step 3, 100% of the MA

The steps of outer ring is the same as inner ring.

Please see picture 11

Figure 3

Remark.

1, The install blot grade must be over grade 10.9.

2, The install power only can be on the bearing rings, not on the roller.

3, In the mounting and dismounting of bearing, the units of bearings can not be Splited and can not change.

4.If the bearings rotate hard, please release the Mounting bolt, tighten the fixing screws in crosswise sequenceusing a torque wrench in three steps to the specified tightening torque.

*X* Do not knock the bearing when install it.

Notes: Other Non-regular models installation, Please be free to contact Hongyuan.

- YRT rotary table bearing

- YRTS rotary table bearing (high speed series)

- YRTM with integral angular measuring system series

- ZKLDF axial angular contact ball bearing series

- RA series crossed roller bearing

- SX series crossed roller bearing

- CRBH series crossed roller bearing

- RE series crossed roller bearing

- RU series crossed roller bearing

- RB series crossed roller bearing

- XR/JXR series crossed taper roller bearing

- Crossed roller bearing

✉️ bearing20@hyzcgroup.com

📞 +86 15236685001