Belt drive installation requirements and usage (1) When installing the transmission belt, the distance between the two wheels should be reduced before the belt can be put on. Do not pry hard to avoid damage to the belt and reduce its service life. (2) When installing the pulley, the axes of the two pulleys must be parallel; the center line of the wheel groove must also be aligned, otherwise it will cause premature wear of one side of the working surface of the V-belt. (3) When selecting a belt, the model and nominal length must not be mistaken to ensure that the cross section of the V-belt is in the correct position in the groove. (4) When there are a large number of V-belts in the same transmission, belts of different lengths and new ones cannot be used to avoid uneven load distribution and accelerated belt wear. (5) Strictly prevent the tape from coming into contact with mineral oil, acid, alkali and other media to avoid deterioration. It is also not suitable to be exposed to the sun. (6) In order to ensure safe operation, the belt drive must be covered with a protective cover. Belt transmission is generally divided into parallel belt transmission, V-belt transmission and synchronous toothed belt transmission.

We have rich experience in precision bearing manufacturing and are ranked NO.1 in China and NO.3 all over the world.

We can tailor the overall solution for the use of precision bearings.

HONB– Accountability & Innovation

- YRT rotary table bearing

- YRTS rotary table bearing (high speed series)

- YRTM with integral angular measuring system series

- ZKLDF axial angular contact ball bearing series

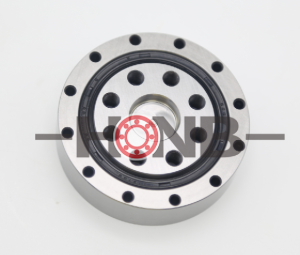

- RA series crossed roller bearing

- SX series crossed roller bearing

- CRBH series crossed roller bearing

- RE series crossed roller bearing

- RU series crossed roller bearing

- RB series crossed roller bearing

- XR/JXR series crossed taper roller bearing

- Crossed roller bearing

✉️ bearing20@hyzcgroup.com

📞 +86 15236685001