Section 3 Basic Production Process of Rolling Bearings

Due to the different types, structural types, tolerance levels, technical requirements, materials and batch sizes of rolling bearings, their basic production processes are not exactly the same. 1. Processing process of main parts of various bearings: 1. The processing process of the ferrule: The processing of the inner ring and outer ring of the bearing varies according to the raw material or blank form. The process before turning can be divided into the following three types. The entire processing process is: bar material or pipe material (Some bars need to be forged, annealed, and normalized) —- Turning —- Heat treatment —- Grinding —- Grinding or polishing —- Final inspection of parts —- Anti-rust—-warehouse—-(to be assembled) 2. The processing process of steel balls also varies according to the state of the raw materials. The process before crushing or polishing the ball can be divided into the following three types. The process before heat treatment can be divided into the following three types. Two types, the entire processing process is: cold punching of bars or wires (some bars need to be punched and annealed after cold punching) – frustrating, rough grinding, soft grinding or light ball – heat treatment – —Hard grinding—-Fine grinding—-Precision grinding or grinding—-Final inspection grouping—-Rust prevention, packaging—-Storage <to be assembled>. 3. The processing process of rollers The processing of rollers varies depending on the raw materials. The process before heat treatment can be divided into the following two types. The entire processing process is: bar turning or cold heading of wire rod, ring belt stringing and soft grinding. —-Heat treatment—-Soft spots—-Rough grinding outer diameter—-Rough grinding end face—-Final grinding end face—-Fine grinding outer diameter—-Final grinding outer diameter —-Final inspection grouping—-rust prevention, packaging—-warehousing (to be assembled together). 4. The processing process of cage The processing process of cage can be divided into the following two categories according to the design structure and raw materials: (1) Sheet material → shearing → punching → stamping → shaping and finishing → pickling or shot blasting or string polishing → final inspection → rust prevention and packaging → warehousing (to be assembled in a set) (2) The processing process of the solid cage: The processing of the solid cage varies depending on the raw materials or roughness. Before turning, it can be divided into the following four blank types. The entire processing process is: bar, Pipe materials, forgings, castings—-inner diameter, outer diameter, end face, chamfering—-drilling (or drawing, boring)—-pickling—-final inspection—- Anti-rust, packaging—-storage <to be assembled>.

2. Assembly process of rolling bearings: Rolling bearing parts such as inner rings, outer rings, rolling elements and cages, etc., after passing the inspection, enter the assembly workshop for assembly. The process is as follows: Demagnetization and cleaning of parts → Group selection of inner and outer rolling channels → Fitting → Check clearance → Rivet cage → Final inspection → Demagnetization, cleaning → Rust prevention, packaging → Put into finished product warehouse (packing and shipping) 〉.

Section 4 Characteristics of rolling bearings

Compared with sliding bearings, rolling bearings have the following advantages:

1. The friction coefficient of rolling bearings is smaller than that of sliding bearings, and the transmission efficiency is high. Generally, the friction coefficient of sliding bearings is 0.08-0.12, while the friction coefficient of rolling bearings is only 0.001-0.005; 2. Rolling bearings have been standardized, serialized and universal, suitable for mass production and supply, and are very convenient to use and maintain; 3. Rolling bearings are made of bearing steel and undergo heat treatment. Therefore, rolling bearings not only have high mechanical properties and long service life, but also can save the more expensive non-ferrous metals used in manufacturing sliding bearings; 4. The internal clearance of the rolling bearing is very small, and the machining accuracy of each part is high. Therefore, the operating accuracy is high. At the same time, the rigidity of the bearing can be increased through preloading. This is very important for precision machinery; 5. Some rolling bearings can bear both radial load and axial load, so the structure of the bearing support can be simplified; 6. Due to the high transmission efficiency of rolling bearings and low heat generation, the consumption of lubricating oil can be reduced, making lubrication maintenance easier; 7. Rolling bearings can be easily applied to uranium in any direction in space.

However, everything is divided into two, and rolling bearings also have certain shortcomings, mainly: 1. The load-bearing capacity of rolling bearings is much smaller than that of sliding bearings of the same volume. Therefore, the radial size of rolling bearings is large. Therefore, sliding bearings are often used in situations that bear large loads and require small radial dimensions and compact structures (such as internal combustion engine crankshaft bearings); 2. The vibration and noise of rolling bearings are large, especially in the later stages of use. Therefore, rolling bearings are not suitable for occasions where high precision is required and vibration is not allowed. Generally, sliding bearings are better. 3. Rolling bearings are particularly sensitive to foreign matter such as metal shavings. Once foreign matter enters the bearing, intermittent large vibrations and noise will occur, which may also cause early damage. In addition, rolling bearings are also prone to early damage due to metal inclusions. Even if early damage does not occur, the life of rolling bearings has a certain limit. In short, the life of rolling bearings is shorter than that of sliding bearings.

We have rich experience in precision bearing manufacturing and are ranked NO.1 in China and NO.3 all over the world.

We can tailor the overall solution for the use of precision bearings.

HONB– Accountability & Innovation

- YRT rotary table bearing

- YRTS rotary table bearing (high speed series)

- YRTM with integral angular measuring system series

- ZKLDF axial angular contact ball bearing series

- RA series crossed roller bearing

- SX series crossed roller bearing

- CRBH series crossed roller bearing

- RE series crossed roller bearing

- RU series crossed roller bearing

- RB series crossed roller bearing

- XR/JXR series crossed taper roller bearing

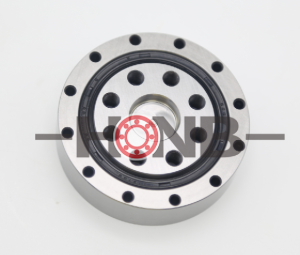

- Crossed roller bearing

✉️ bearing20@hyzcgroup.com

📞 +86 15236685001